Hot Forged Fasteners for Critical Industrial Applications

Manufacturer of hot forged fasteners conforming to ASTM / ASME standards including SA193, SA194, SAE, JIS, ISO & DIN specifications, in alloy steel, stainless steel, Inconel, Duplex & Super Duplex for Oil & Gas, Power, Nuclear and Process Industries.

Manufacturing Strength

Advanced Manufacturing Capabilities

In-house processes designed for strength, precision, and compliance.

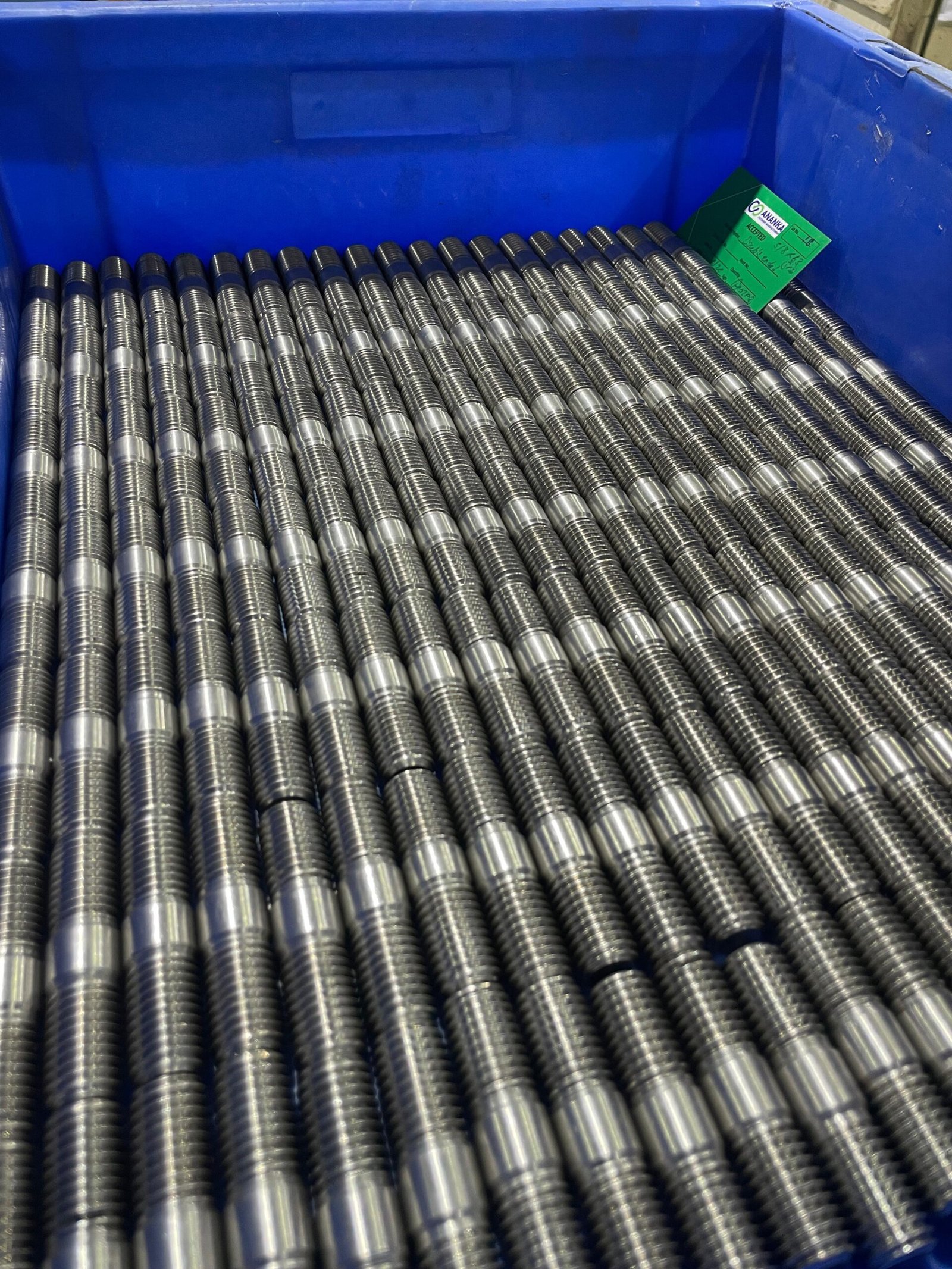

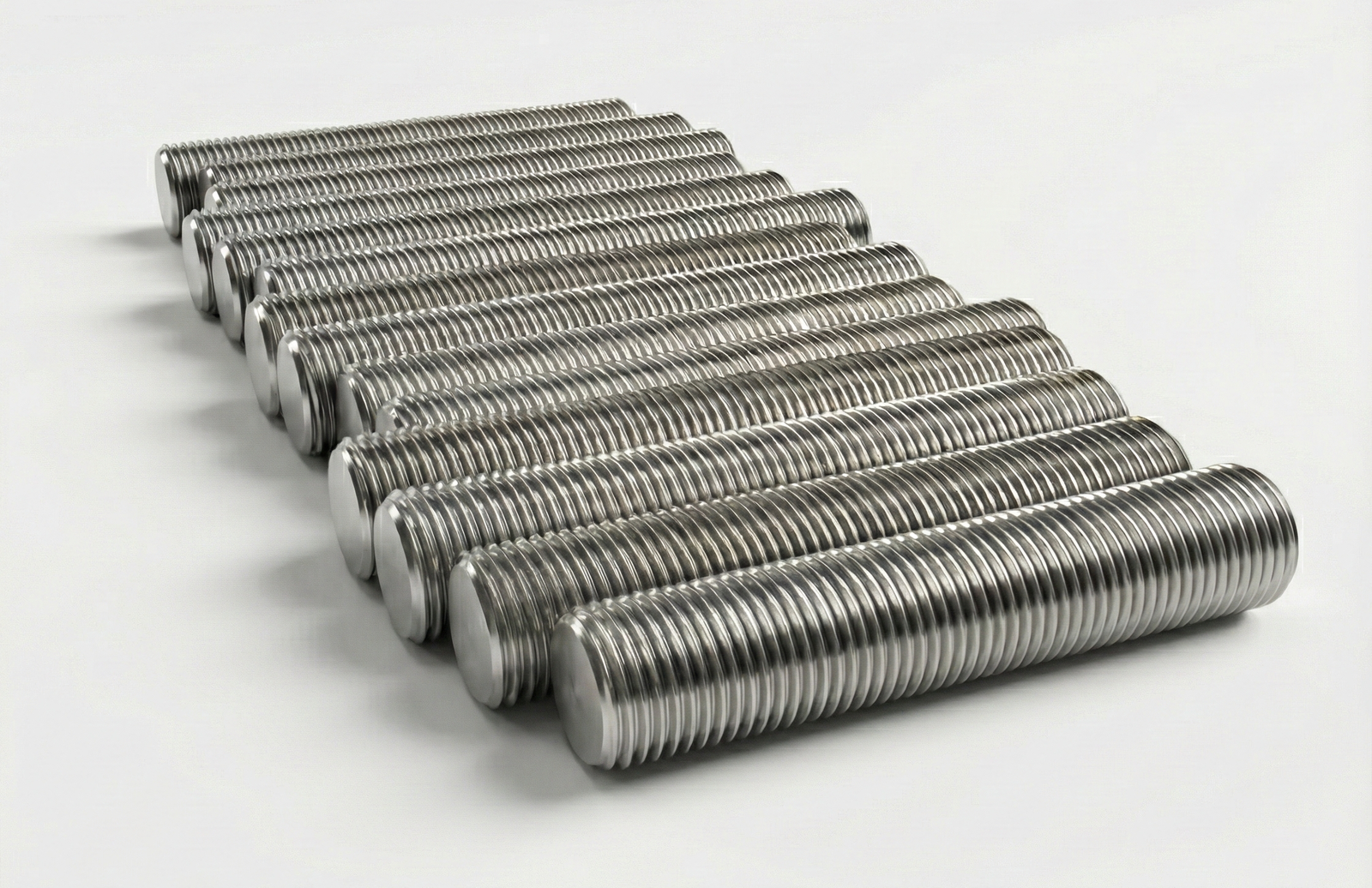

Roll Threading

Cold thread rolling process ensuring superior grain flow, high fatigue strength, and dimensional accuracy for critical fasteners.

Heat Treatment

Controlled heat treatment processes to achieve required mechanical properties, hardness, and long-term durability.

CNC Machining

Precision CNC machining for tight tolerances, complex geometries, and custom non-standard fastener requirements.

PRODUCT RANGE

Fastener Product Portfolio

Manufacturing a wide range of industrial fasteners for critical applications.

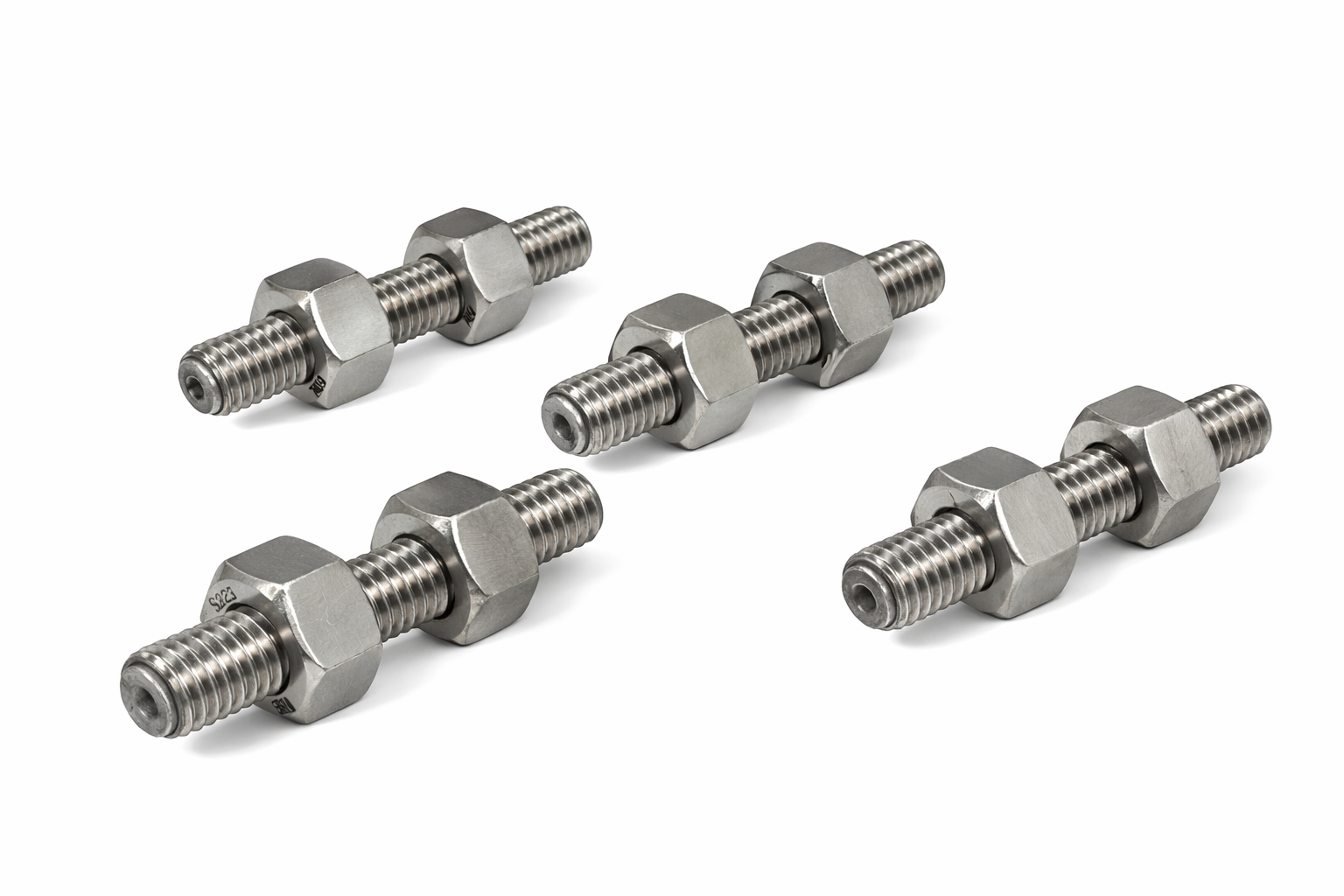

Bolts

DIN / ISO / ASTM / ASME

Nuts

DIN / ISO / ASTM / ASME

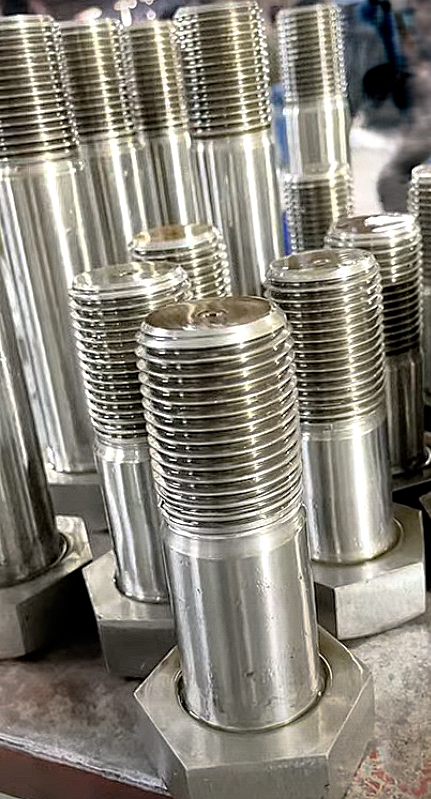

Studs

DIN / ASTM / ASME

Washers

DIN / ISO / ASTM / ASME

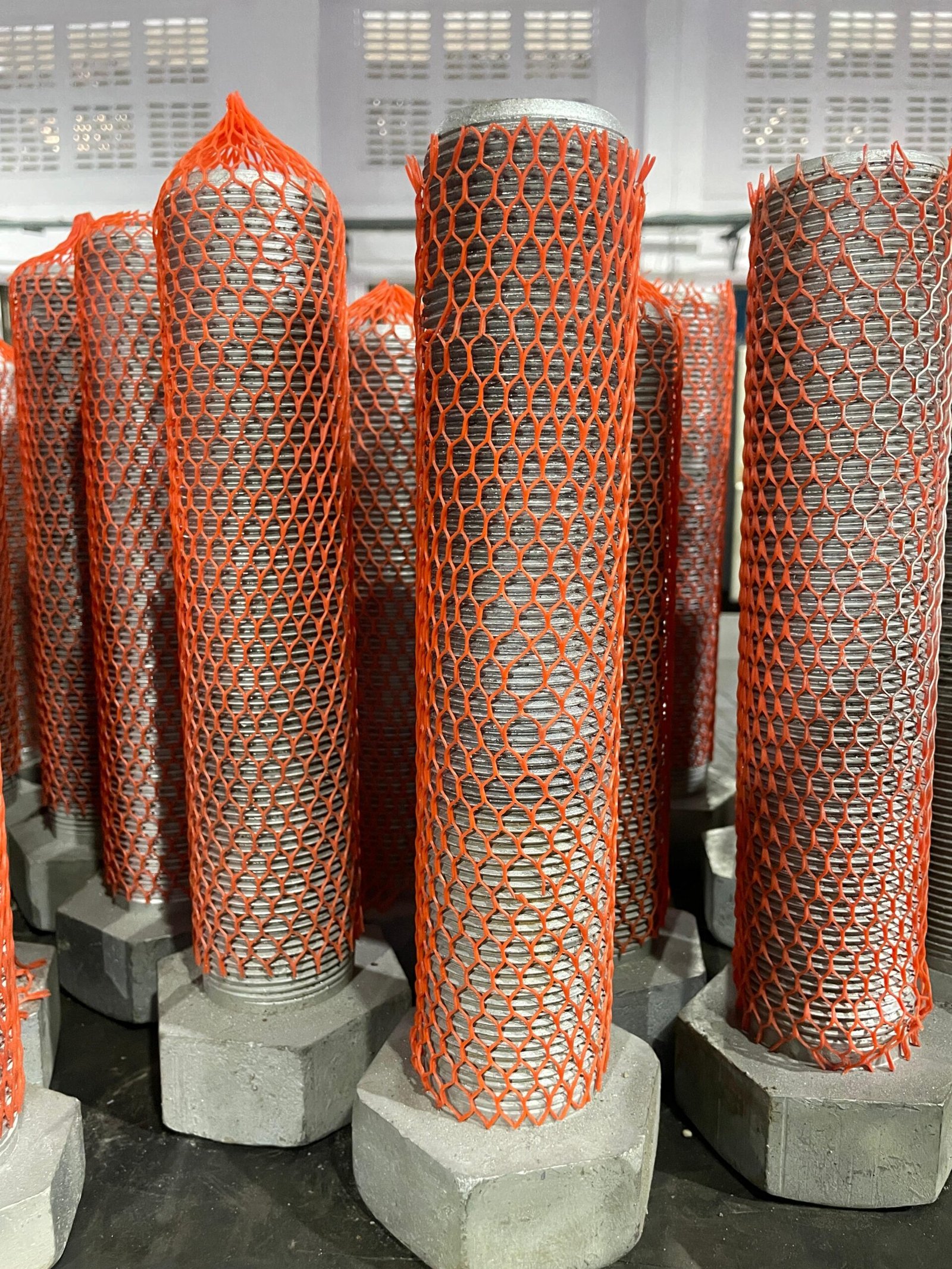

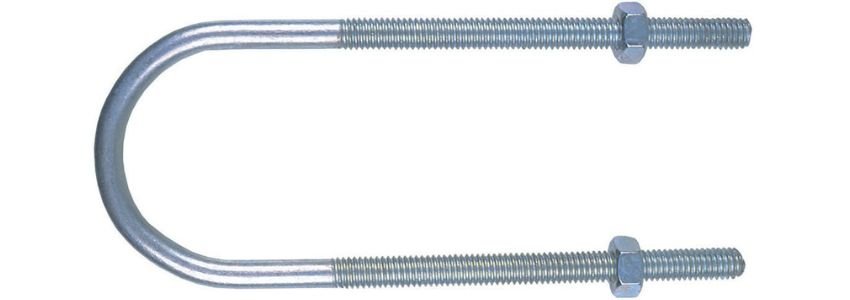

Anchor Bolts

ASTM / DIN / ISO

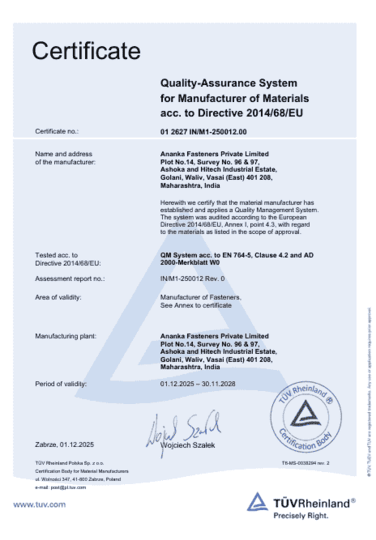

Compliance

Certifications & Standards

International compliance for pressure equipment and critical applications.

Industries We Serve

Our fasteners are engineered for critical applications across demanding industrial sectors.

Oil & Gas

Pressure Vessels

Refineries

Reactors

Offshore Projects

Power & Nuclear

Marine & Shipbuilding

Subsea Structures

CLIENT FEEDBACK

Trusted by Industry Leaders

Powering critical projects for India's biggest engineering giants.

“Ananka supplied high-pressure steam turbine fasteners that met our rigorous quality checks. Their adherence to BHEL technical specifications and timely delivery for our thermal power projects is commendable.”

“We rely on Ananka for high-tensile structural bolts for our major infrastructure and metro projects. Their material traceability and consistency in large-volume orders make them a trusted partner.”

“Excellent supply of corrosion-resistant alloy studs and nuts for our refinery maintenance turnaround. They understand the critical safety standards required in the Oil & Gas sector.”

“Ananka Fasteners has consistently supported our steel plant operations with heavy-duty fastening solutions. Their ability to deliver customized sizes on short notice helped minimize downtime.”

“Precision is non-negotiable for our turbines. Ananka delivered fasteners with exact tolerance levels and complete documentation, meeting our global engineering standards.”

“Supplying to the aerospace sector requires zero error. Ananka provided specialized alloy fasteners that passed all our stringent material testing and stress analysis requirements.”

Materials, Grades & Standards

ASTM / ASME / EN / ISO / DIN / SAE compliant materials with full traceability

Nickel, Titanium & Non-Ferrous

High-performance alloys for extreme environments

Nickel & Special Alloys Critical

Titanium

- Grades 1, 2, 3, 4

- Grade 5 (Ti-6Al-4V)

- Grade 7

Non-Ferrous & Reactive Metals

- Aluminium Bronze

- Phosphor Bronze

- Manganese Bronze

- Copper

- Cupro Nickel 90/10 & 70/30

- Tantalum

Stainless Steel, Duplex & PH

Corrosion-resistant materials for chemical & offshore service

Austenitic Stainless Steel

- 304 / 304L

- 316 / 316L

- 317 / 317L

- 310, 321, 347, 904L

Bolting Stainless (SA193)

- B8, B8A, B8M, B8MA

- B8C, B8T

- B8S (Nitronic 60)

Precipitation Hardening

Duplex & Super Duplex

- Duplex 2205 / 2304

- Super Duplex 2507

- Zeron 100

- SMO 254, AL-6XN

Standards

- ASTM A193 / A194

- ASTM A276 / A240

- ASTM F593 / F594

- ASTM A182

Carbon & Alloy Steel

For pressure, temperature & structural applications

SA193 / SA194 Bolting Grades Popular

- SA193: B5, B6, B7, B7M, B16, B16X

- SA194: 1, 2, 2H, 2HM, 4, 4H, 7, 7M, 8, 8M

- Carbon Steel: Grade 3

Low & High Temperature Service

- ASTM A320: L7, L7M, L43, L43M

- ASTM A105

- ASTM A350: LF1, LF2, LF3

- ASTM A694: F52, F60, F65

Alloy Steel (International)

- EN Series: EN8, EN9, EN19, EN24

- SAE Grades: 4130, 4140, 4340

- ASTM A182: F1, F5, F9, F11, F12, F22

- 17CrNiMo6

The coffee is on us.

The solutions are for you.

Skip the emails. Come visit our HQ to discuss your pressure vessel and fastener requirements face-to-face.

Let's Start a Conversation

Request technical data sheets, price quotes, or custom fabrication details. Our engineering team is ready to assist with your requirements.

Send Your Requirement

Fill out the form and we'll respond within 24 hours